Technical Insights

NEW PRODUCT RELEASE: SUPER S® WIRESEAL CORROSION INHIBITORS

Roseland, LA - Smitty's Supply Inc has announced the release of an exciting new product to our industrial lubricants product line. WireSeal corrosion inhibitors provide long-life lubrication to wire ropes. The robust, tacky formulation developed by our in-house R&D Department may also form excellent seals in downhole applications sealing out contaminants and prohibiting leakage of oil. They contain a specially selected corrosion inhibitor to protect against attacks by H2S and CO2 commonly found in many industrial work environments. Currently produced in 3 viscosity grades (680, 1500, and 2500), WireSeal can be tailored to each customers application. If you have specific questions prior to ordering, please contact our Technical Service Department for additional information. Follow the link below for more detailed information on the uses of WireSeal Corrosion Inhibitors.

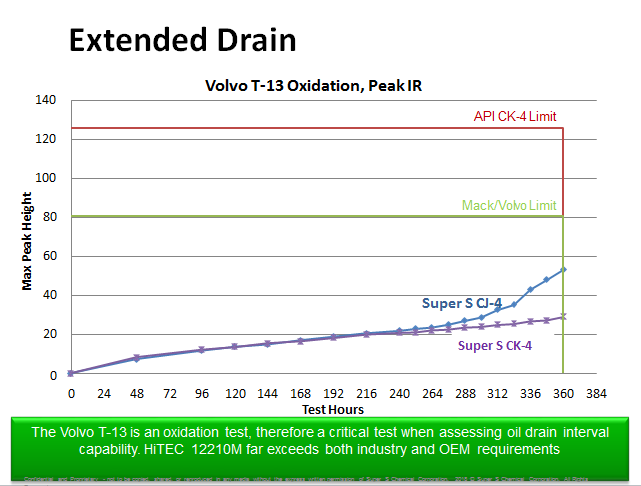

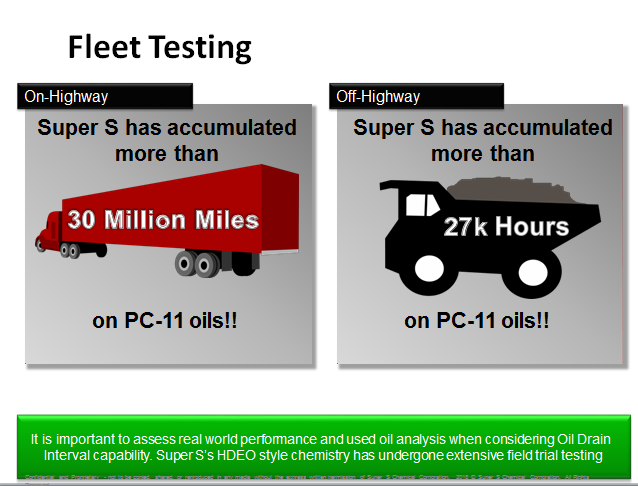

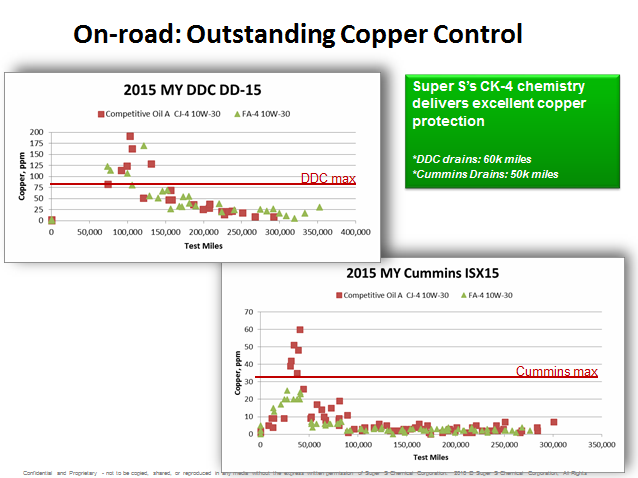

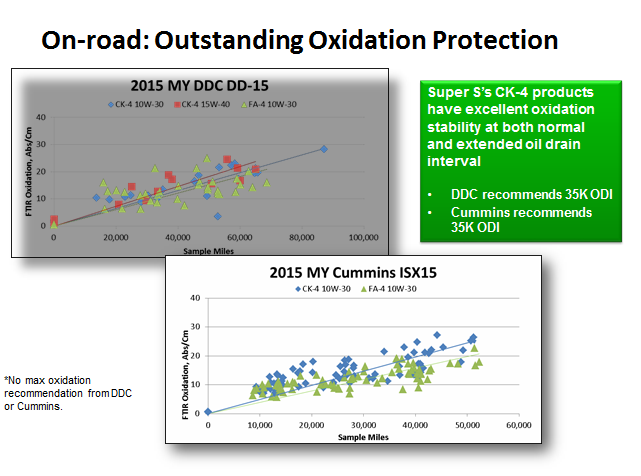

Super S® FG-2000 CK-4 Engine Oils show Excellent Performance in Extended Drain Applications

Roseland, LA

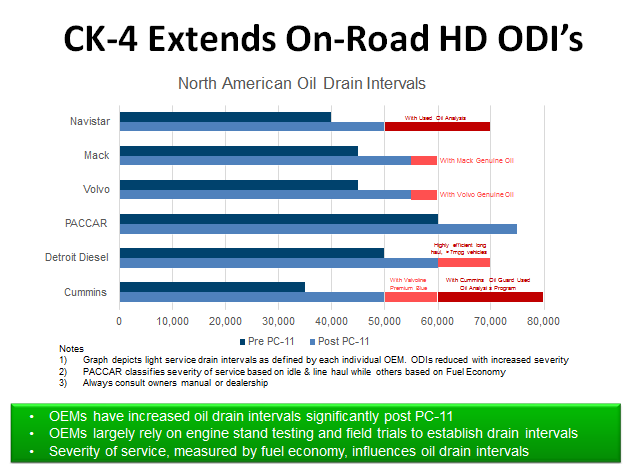

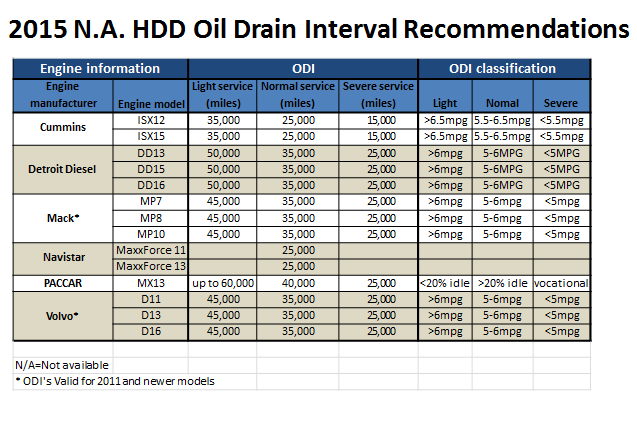

The release of PC-11 brought concerns from OEMs that the lack of anti-wear agents (Phosphorus/Zinc) combined with lower TBN would not sufficiently protect all engines operating in all environments as previous API categories did. This prompted the introduction of several manufacturer specific specifications most notably from Ford. Two years removed from it's December 1, 2016 release, and PC-11 engine oils have proven robust enough to provide extended drain protection in most heavy duty engines. Below we take a look at how the introduction of CK-4 engine oil has affected oil drain intervals in North American heavy duty applications.

TACKLING THE "NEED TO KNOW" ON API SN PLUS

First, why did the API decide to release SN Plus ahead of the impending GF-6 update?

API SN Plus was proposed by ILSAC on July 20, 2017 and reviewed further by the industry at the API LG Standards meeting on Aug 15, 2017. With delays in test stand development for ILSAC’s new GF-6 performance category, GM found it necessary to release an improved engine oil specification to address a newly discovered phenomena found in Turbo Gasoline Direct Inject (TGDI) engines called Low Speed Pre-Ignition (LSPI). The next generation additive system showed improvements in fuel economy, engine cleanliness, and included a new direction chemically in the detergent system that drastically reduces occurrences of LSPI. The increasing impact of LSPI left the other OEM’s scrambling for a solution of their own. This prompted original equipment manufacturers (OEMs) to request immediate implementation of a supplement to ILSAC GF-5 to protect turbo gasoline direct injected (TGDI) engines from catastrophic damage. The proposed API SN Plus supplement is not a new category and will be available alongside the current API SN and ILSAC GF-5 categories. This unprecedented request from OEMs highlights the severity of low speed pre-ignition (LSPI) and confirms the immediate need for higher performing lubricants to protect against damage.

What is GF-6 and why has the test development process been so complicated?

In 2012, the International Lubricants Standardization and Approval Committee (ILSAC) announced they were working on a new PCMO engine oil specification to replace the current GF-5. This specification had a planned release date of January 1, 2015 and was intended to Increase Fuel Economy, Enhance Oil Robustness, Expand Overall Fuel Efficiency, Improve Wear Protection, and Reduce Engine Aeration. Complications arose while developing the new engine tests as at least 3 new tests are expected to address Fuel Economy, Wear, Oxidation & Piston Deposits, and Sludge & Varnish Formation. The new tests were needed to not only address the upgrades in engine technology, but to also be viable for evaluating the new lower viscosity grades. These lower viscosity grades (0W-16 and below) will be identified as GF-6B while the normal viscosity grades (0W-20 and up) will be identified as GF-6A. Finding a chemical balance that provides adequate protection across all viscosity grades has shown to be a challenging task. What an oil needs to perform in low temperatures can be the same components that produce ash in high temperatures and vice versa. Holistic solutions have been required to provide the robust protection required in tomorrow’s engines.

Does my car require SN Plus engine oil?

Unless your automobile recently drove off the assembly line, it’s doubtful you will require the protection provided by the SN Plus supplemental category. Although with the number of TGDI engines in service growing by the minute, you could see SN Plus oils recommended with your next purchase.

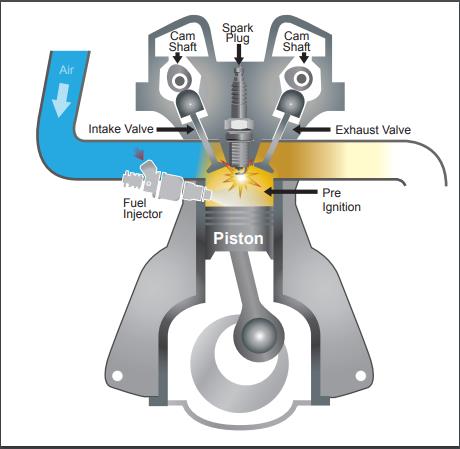

What is LSPI?

LSPI is the spontaneous ignition of the fuel/air mixture before spark-triggered ignition. It is another version of pre-ignition. Pre-ignition (engine knock) has been around since the beginning of internal combustion engines. LSPI, however, occurs under low-speed, high-torque conditions, such as taking off from a stoplight in T-GDI engines. This scenario can create conditions where the fuel/air ignites too early in the combustion cycle, throwing off the engine’s timing. The expanding combustion charge collides with the piston as it’s moving up the cylinder, potentially destroying the pistons or connecting rods.

Can engine oil prevent LSPI?

Experts suggest the cause is due in part to oil/fuel droplets or deposits in the cylinder igniting randomly. The droplets and deposits contain enough heat to ignite the air/fuel mixture before spark-triggered ignition. Oil formulation can play a role in reducing LSPI. Certain motor oil ingredients can promote LSPI, while others can help reduce it. It’s tempting to think, “Well, dump a bunch of ingredients into your formulations that help reduce LSPI.” But some ingredients that help reduce LSPI have been limited over the years in motor oil formulations for other reasons. It truly is a scientific balancing act confronting oil formulators. It’s no easy task to formulate motor oils that deliver excellent wear protection, resist the increased heat of turbocharged engines, prevent deposits, act as a hydraulic fluid and, now, combat LSPI. The performance of the entire formulation – not just one or two ingredients – is what counts.

What is the consequence for not using a SN Plus rated oil where required?

LSPI, or super knock, can lead to catastrophic damage to pistons and rods leading to very expensive repairs. LSPI events are known to happen at random and in series with each other giving little warning to the driver. SN Plus rated products from Smitty’s provide the protection required to eliminate LSPI occurrences.

UNDERSTANDING RV ANTIFREEZE PROTECTION

Freeze Protection vs Burst Protection

With so many different types of antifreeze currently available in the market, it can become confusing trying to differentiate and help advise customers on choosing the appropriate product for their application. So what seperates antifreeze products and makes one more suitable over another? Below we will explain the process for selecting the correct antifreeze and attempt to expplain what seperates a RV antifreeze from an Engine Coolant.

First and foremost, just as with mechanical lubricants, it starts with the base oil, in this case, glycol. For automobile use, ethylene glycol is the preferred choice as it’s solubility of additives, boil over and corrosion protection, and compatibility with the internal components in cooling systems is superior to diethylene or propylene glycol. Propylene glycol with its superior freeze protection along with being more eco-friendly makes it the preferred choice for homes, RVs, or anywhere it may come into contact with the environment.

We now have chosen our base oil based on our application’s needs, so now we will need to tailor our base oil to fit our customers’ needs while also providing them a cost effective option. Since we are talking RV antifreeze, we could package 100% Propylene glycol (with its freeze point in the -60F range) with a small amount of corrosion inhibitor and provide protection down to -100F and with that our price would be approximately 4x that of our current product. But wait a minute, you just said that Propylene Glycol has a freeze point around -60F, so why are we now talking -100F. Here’s where the marketing department comes into play.

There are 2 main terms when referencing antifreeze protection, Freeze Protection and Burst Protection. If you pay close attention you will see there can be a sizable difference in the 2 temperatures for the same product. Several commercially available RV Antifreeze products claim -60F Freeze Protection with Burst Protection to -100C. The difference is Freeze Protection is the temperature at which ice crystals begin to form. Once the smallest crystals begin to form, the other molecules now have something to attach themselves to leading to slush. In a combustion engine or other critical applications where on demand pumping of coolant is critical, preventing the growth of ice crystals is imperative, but in RVs where the coolant will not flow rather just sitting in the system, preventing ice crystal formation is not as important and would require the use of a much more expensive product..

Burst Protection is the temperature at which a sealed copper pipe filled with undiluted product will burst. Take a minute to process that, burst a copper pipe. When talking about our home or RV, this is all that we ask our antifreeze to do is keeps us from having to repair pipes during the winter months. In this case, we do not need protection down to -100F as even in the coldest climates in our country we rarely go below -20F, and most places do not get that cold. So, to provide cost relief to the customer, blenders dilute the RV concentrate with deionized water, just as with auto antifreeze, targeting Burst Protection in the -50 to -60⁰F range. This would make the actual freeze point where slush begins to form to be much higher, but again freeze protection is not critical in this specific application.

So, when helping a customer choose the proper antifreeze solution for a specific application, there are a couple questions we can ask to narrow down our choices.

- Type of system needing protection (auto, home/rv, marine)

- Operating and stationary temperature ranges (boiling protection is just as critical as freeze protection)?

- What temperature do I need Freeze Protection to and also what temperature do I need Burst Protection?

- Are there any environmental concerns (contact with sewage waste water, etc)?

- What types of metal/alloys will the product be in contact with (different additives provide more/less protection to different types of metal)?

- How long does the antifreeze need to last?

- Is there an OEM specification required?

Asking yourself the above questions, can help you narrow down the choices, but if you are still unsure, you can always contact our technical Department for more detailed information. If you receive complaints from customers regarding the formation of slush with the RV Antifreeze at temperatures above -50⁰F, you can put their concerns to ease by explaining the product is doing what it is intended to do, providing Burst Protection to a specified temperature, and if they were to compare a competing product, they would find the same level of protection exists between brands. The major difference is how the marketer chooses to put their label together. For further explanation, please contact Jeremy or Matt in our Technical Department.